Dezincification Vs. Stress Corrosion Cracking: What’s the Difference?

Copper piping remains one of the most common materials for potable water systems, especially for hot water installations. Brass fittings and valves are typical in copper pipe systems and may fail under a variety of circumstances. When these fittings fail, it is the job of forensic engineers to figure out the mechanism that caused them to fail.

Two of the most common failure modes of brass fittings are dezincification (DZ) and stress corrosion cracking (SCC).

Dezincification

Dezincification is a type of corrosion of brass. Brass is an alloy, meaning that it is a metal product made up of a mixture of two or more metals. Typically, the constituent metals are melted, mixed, and then hardened to form an alloy with a near uniform distribution of each metal. In the case of brass, it is a mixture made up primarily of copper and zinc.

With dezincification, the zinc in brass will react with the dissolved chemicals in water within the fitting, and as a result, can be pulled out of the brass. This leaves behind a weak and spongy copper material that cannot withstand typical water pressure and can easily lead to water leaks.

Dezincification happens more often with brass of a zinc content = 15%, and much more often when the zinc content is = 35%. Apart from base composition, other factors that can contribute to the rate of dezincification include water quality, material additives, and manufacturer heat treatment.

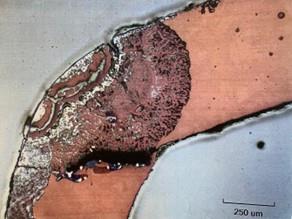

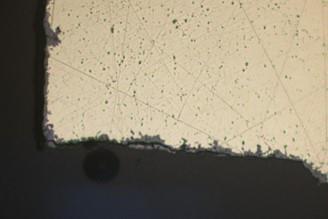

Photographs 1 and 2: Fitting Cross-Sections Showing Plug Type (1) and Layer Type (2) Dezincification

Two Types of Dezincification

There are two main types of dezincification: plug type and layer type.

Plug type is characterized by a localized spongy area of material, typically penetrating more deeply than layer type. Layer type is characterized by a thinner layer of spongy material spread out across an entire exposed surface. Plug type typically happens faster and occurs when brass is exposed to neutral or alkaline waters (pH <7), high salt content in water, and water with a temperature greater than that of the room.

Layer type instead occurs with slightly acidic water, low salt and mineral content, and high in chloride ions. Chloride ions are present in most water from dissolved salts. Chlorine and/or chloramine is commonly found in water and are added in low concentration to public water supplies to control microorganisms. Dezincification is most often caused by improper material selection when the fitting is manufactured, low-quality materials, or improperly treated water.

Stress Corrosion Cracking

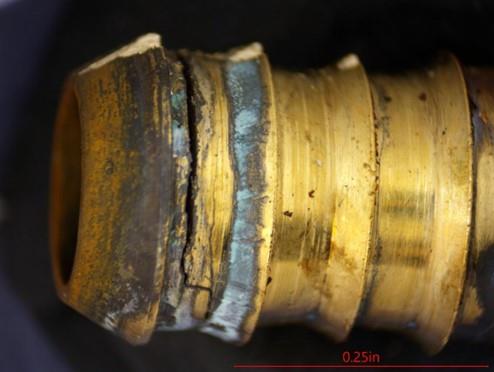

Stress corrosion cracking is a similar but different failure mechanism from dezincification. It is not specific to just brass but is commonly observed in brass failures. In short, stress corrosion cracking is a result of a combination of stress, corrosive elements, and a susceptible material, leading to failure. The higher the stress, the more corrosive the environment, or the more susceptible the material, the faster stress corrosion cracking will occur.

Common Causes of Stress Corrosion Cracking

Common causes of stress corrosion cracking are overtightening of threaded fittings (high stress), a brass fitting with a high zinc content (a susceptible material), and ammonia in the water (a corrodent). Some amount of ammonia is almost always present in public water supplies, and a very small amount of it, when combined with a brass fitting and high stress, can lead to stress corrosion cracking.

Stress corrosion cracking is most commonly brittle, meaning there is not much deformation before failure, and cracks typically follow grain boundaries in metals (referred to as intergranular cracking). Secondary branching cracks are also common in cases of stress corrosion cracking.

Photograph 3: Example of SCC in Brass Fitting

Importance of the Distinction of Failures

By understanding and identifying which mechanism was the root cause of a plumbing component failure, future failures due to dezincification and stress corrosion cracking can be prevented. Since each mechanism requires different circumstances to initiate and progress, the appropriate corrective measures will vary based on the precise mechanism of failure.

It may be necessary to characterise the specific cause of brass component failures to characterize the contributions to the failure by each involved party so that liability can be determined during legal proceedings.

Material Failure Analysis

At Envista Forensics, we specialize in understanding and analyzing the material properties behind product failures. Whether it's corrosion, fatigue, or defective materials, our expert engineers use state-of-the-art tools and techniques to identify the root cause of failures and provide actionable insights for prevention.

With extensive experience in materials like metals, plastics, ceramics, and more, we deliver precise, scientifically backed conclusions that help you make informed decisions and avoid future issues.

If you're dealing with a material failure, contact Envista Forensics today.

Our specialists are ready to provide expert analysis and guide you through every step of the investigative process.

Let us help you solve your engineering challenges and ensure the durability of your materials and products.

Our experts are ready to help.