Leveraging Advanced Structural Analysis Tools in Engineering and Forensic Applications

Structural mechanical analysis is crucial in forensic engineering, providing valuable insights into the integrity and failure mechanisms of structures. Advanced tools and methodologies assess stresses and strains within materials, predicting potential failure points and aiding in the design of resilient structures.

Ensuring Code Compliance and Structural Safety

Assessing structural integrity against building codes is critical for engineers. Advanced software compares designs and performances against standards such as the Ontario Building Code, International Building Code, and relevant material codes, including the Canadian Steel Code, ensuring that columns and beams operate within safe capacity limits. This includes worst-case scenarios such as extreme snow loads or windstorms that could lead to structural failure. The software predicts deflection limits, maintaining occupant safety and comfort.

Enhancing Industrial Efficiency Through Targeted Structural Analysis

In industrial engineering, optimizing machinery and equipment structural integrity is vital. For example, reinforcing specific crane parts with new steel instead of replacing the entire crane saves costs. Similar approaches apply to pressure vessels, where Finite Element Analysis (FEA) models simulate conditions and identify failure points for targeted repairs, avoiding complete replacements and saving resources.

Managing Structural Integrity in High-Temperature Environments

Designing and maintaining industrial furnaces involves managing electrical energy, structural integrity, and material properties. Furnace electrodes generate power and magnetic fields that can induce currents in supporting steel structures, risking overheating and failure. Advanced design techniques, such as using stainless steel for roofs and ceramic plates to break electrical connections, ensure safe and efficient furnace operation, extending lifespan and maintaining structural integrity.

The Power of Advanced Structural Analysis Tools

Advanced structural analysis tools, like SAP 2000, Risa, E-tabs, and Staad Pro, have transformed engineers' approach to complex structural problems. These software programs enable the creation of detailed models that simulate structural behavior under various loading conditions.

By inputting parameters such as material properties, load types, and boundary conditions, engineers can accurately predict a structure's response to different forces, which is particularly valuable in forensic engineering for identifying failure causes. For example, in a building collapse investigation, these tools can determine whether the failure resulted from design flaws, material defects, or unexpected loading conditions.

One significant benefit of advanced structural analysis tools is their ability to handle complex geometries and load combinations, which are impractical for traditional hand calculations. The software processes thousands of calculations quickly, providing comprehensive analyses that would be time-consuming and error-prone manually.

This efficiency allows engineers to explore multiple design scenarios and optimize structures for safety and performance. Additionally, these tools can simulate dynamic events like earthquakes or wind loads, offering insights into structural behavior under extreme conditions.

Forensic Engineering Applications and Structural Insights

Identifying Failure Causes in Structural Investigations

In forensic engineering, detailed structural analysis is crucial for identifying failure causes and developing remediation strategies. For instance, in a collapsed bridge investigation, these tools can model the bridge's response to various loads and pinpoint critical failure points.

This information helps improve future designs and prevent similar incidents. Advanced analysis techniques also assess the remaining life of aging structures, aiding in maintenance and repair prioritization. Understanding a structure's current state and predicting its future performance enables informed decisions that enhance safety and reliability.

Specialized Tools for Component-Level Analysis

The software used for structural analyses is sophisticated and capable of performing global building assessments for code compliance. However, it has limitations in analyzing small, intricate components like bolted connections between beams and columns, requiring specialized tools for detailed analyses. Engineers use these tools to simulate scenarios, including unexpected loads or design defects, to determine structural failure causes, which is particularly useful in forensic engineering and litigation.

Advanced Modeling Techniques: FEA, CFD, and DEM

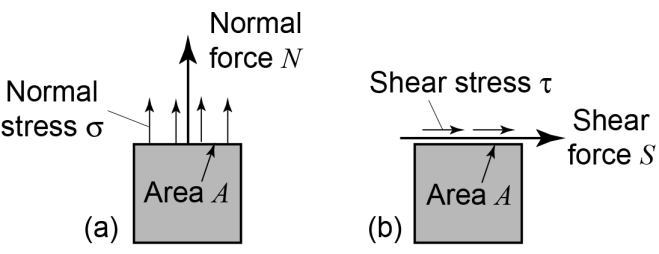

Finite Element Analysis (FEA) is another advanced method for modeling and analyzing structures in 3D. This technique involves breaking down a structure into small polygons, allowing detailed stress and strain analysis on each component. The finer the mesh of polygons, the more accurate the results.

Although FEA can take considerable time for complex models, it provides invaluable insights into how different parts of a structure interact under various loads. This method is essential for designing robust connections and understanding failure points in existing structures.

FEA, CFD, and DEM in Engineering Applications

Applying FEA in Real-World Scenarios

FEA is applied to both structural components and mechanical parts in practical applications. In the automotive industry, it analyzes gears and components under stress. Engineers define boundary conditions and apply loads to simulate real-world conditions, optimizing designs to prevent failures and improve performance. This iterative process often requires multiple runs to refine designs and ensure safety standards are met.

Addressing Temperature Effects in Structural Design

Temperature is critical in structural analysis, especially for components exposed to high heat. Materials expand when heated and exert force if constrained. Pressure vessels operating above 1000°C require careful consideration of thermal expansion to prevent catastrophic failures. Engineers must predict expansion and design structures to accommodate this movement. Smelting furnaces, reaching temperatures over 2000°C, require designs that allow significant expansion, often using springs and other mechanisms to absorb expansion and prevent damage.

Using CFD to Optimize Fluid and Heat Flow

CFD models fluid flow through structures, optimizing designs for components handling high-temperature gases or liquids. In steel production, superheated oxygen is injected into blast furnaces through refractory-lined pipes. CFD analysis identifies wear-prone areas and allows design adjustments to extend component lifespan, improve efficiency, and reduce maintenance costs.

Leveraging DEM for Material Flow Efficiency

DEM focuses on fine particulate behavior, valuable in processes involving pulverized material transportation. In designing hoppers and conveyors, DEM helps identify dead zones where material might accumulate, causing blockages or wear. Understanding these dynamics allows engineers to optimize designs for smooth material flow, enhancing system performance and reliability.

The Future of Structural Analysis in Forensic Engineering

Advanced structural mechanical analysis is crucial in forensic engineering, providing tools to understand material and structural behavior under various conditions. Sophisticated software programs enable detailed analyses to uncover failure causes, informing resilient structure designs.

These capabilities ensure the safety and longevity of buildings, bridges, industrial facilities, and infrastructure. As technology evolves, structural analysis will offer more powerful tools to tackle modern engineering challenges.

Integrating FEA and Modeling for Safer Structures

The integration of advanced software tools and FEA in structural engineering ensures building safety and performance. Detailed analysis of structures and components helps design robust buildings. Simulating different scenarios and loads allows engineers to predict failure points and mitigate risks, enhancing structural safety and durability while supporting forensic investigations with clear evidence.

Enhancing Efficiency and Reducing Costs

Advanced modeling techniques like FEA, CFD, and DEM in industrial engineering allow precise analysis and optimization of complex systems. These tools help predict and prevent failures, optimize designs for efficiency and longevity, and reduce costs by avoiding unnecessary replacements and repairs. Leveraging these technologies, industries achieve higher performance, safety, and reliability.

Designing and maintaining industrial furnaces requires understanding electrical energy, material properties, and structural dynamics. Advanced modeling software, appropriate material selection, and innovative design solutions ensure safe and efficient furnace operation.

Using stainless steel, ceramic isolators, targeted cooling, and stiffening measures extends furnace lifespan, highlighting meticulous design and analysis's role in optimal industrial performance.

Expert Structural Analysis with Envista Forensics

Advanced structural analysis is redefining how engineers and forensic experts understand, design, and protect complex systems. From predicting failure points to enhancing industrial efficiency, these tools empower professionals to build safer, more resilient structures.

At Envista Forensics, our experts harness cutting-edge technologies—FEA, CFD, DEM, and advanced modeling—to deliver precise, data-driven insights for both engineering design and forensic investigations.

Partner with Envista Forensics to unlock the power of advanced structural analysis for your next project or investigation.

Contact us today to speak with our experts and ensure the integrity of your structures.

Nuestros consultores están listos para ayudar.